sefanzed

Members-

Posts

19 -

Joined

-

Last visited

sefanzed's Achievements

Junior Member (2/5)

3

Reputation

-

14 year old Envoy Hot Tub tripping 20 amp breaker

sefanzed replied to sefanzed's topic in Portable Hot Tubs & Spas

I ended up replacing the motherboard and front and aux panels in my Envoy since they were in various states of disrepair. The spa is working great now, and as an update, four years later, the shut-off issue is solved. Going back to my original manual, I found there is a timer that shuts off the spa pumps after two hours of continuous use. I'm looking forward to getting another decade or two out of my spa! -

Hotspring Grandee 2020 remote not working

sefanzed replied to Jchag's topic in Portable Hot Tubs & Spas

When my remote on my 16year old Watkins Envoy goes off-line, I reset the breakers. After a reboot, the remote always works. Hope that helps. -

14 year old Envoy Hot Tub tripping 20 amp breaker

sefanzed replied to sefanzed's topic in Portable Hot Tubs & Spas

Thought I'd update this, if anyone is still interested. The venting solution has been running for about 3-4 weeks now, and I haven't had one shutdown due to extended use. So far, the grand experiment has proved successful. Some observations. When the system is off, the typical temperature inside the equip cabinet ranges between 98-104 degrees (depending on outdoor air temp). When the system is running for more than 45 minutes, the temp can reach 117. Due to the fan exhaust, the cabinet temp tops out at 117 (the fan deploys at 104 and doesn't turn off until it reaches 98). Without the fan the temperature probably surpassed 120+ which instigated the shutdown. Occasionally, the fan does turn on during the day when the sun is shining directly on the equipment cabinet, however, since the fan uses one 3watts or so, this isn't an issue. In the long run, temperature control will probably benefit to extend the life of the equipment. Still, since the components are over 14 years old, that horse has probably left the barn! -

14 year old Envoy Hot Tub tripping 20 amp breaker

sefanzed replied to sefanzed's topic in Portable Hot Tubs & Spas

Thanks! I'll update as more info presents itself. -

14 year old Envoy Hot Tub tripping 20 amp breaker

sefanzed replied to sefanzed's topic in Portable Hot Tubs & Spas

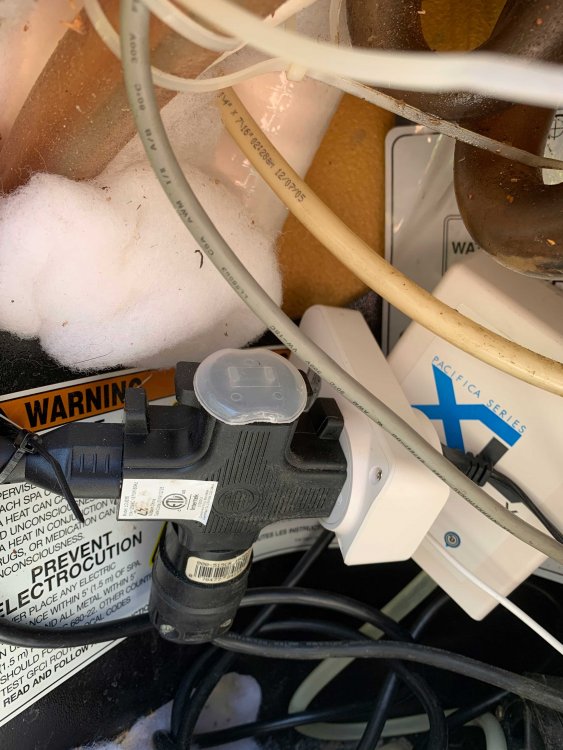

This ozone generator is on all the time as far as I know. I've tested the controller with the pumps on and it appears to be receiving current (remote shows ERR if the untit isn't powered). Here are some pix showing the controller install/temp probe placement (next to IQ2020), fan detail, remote (still futzing with settings) and pix of the spa. All electric items are not touching any surfaces likely to become wet. Initially, my biggest concern was that the signal/rf from the controller transmitter might interfere with my spa remote, but that hasn't been the case, thankfully. So far the only challenge is to set realistic temperatures for the fan operation. The total cost was around $40.00. Until I saw the readout on the remote, I never suspected the equipment area got so hot. Speaks well of the Watkin's engineering team, since their spas have to live through extreme hot and cold, depending on the install locale. I only wish they'd publish some real schematics and tech info, like operating temp ranges, etc. -

14 year old Envoy Hot Tub tripping 20 amp breaker

sefanzed replied to sefanzed's topic in Portable Hot Tubs & Spas

It's on the same circuit as the ozone generator. -

14 year old Envoy Hot Tub tripping 20 amp breaker

sefanzed replied to sefanzed's topic in Portable Hot Tubs & Spas

I've installed the axel fan today, along with a programmable thermostatic controller. I've positioned it above the non-watkins motor, fastening it to the exhaust tubing that used to connect to the back end of the watkins self-exhausting motor. Now it's pulling cooler air into the equipment area and exhausting it to a vent on the side of the spa. There was direct sunlight hitting the equipment compartment cover and initially the inside temp was 105ª with the spa off! I've programmed the fan to turn on at 105 and off at 98. I'm shooting in the dark with pinpointing optimal temperature ranges, but I did want to see how fast the fan would work to cool down the compartment. Having said that, we don't use the spa in the heat of the day, so in actual use the outdoor temps would be cooler, as opposed to daytime when the ambient temp was 79 or so (direct sunlight played a factor today). As I write this, I've gotten the rig up and running for about about 2 hours and the fan has cooled the cabinet down by about 6 degrees. That's why I was trying to pin down the operating temperature range of the IQ2020 circuit board, if for nothing else to gauge how to set the operating parameters of the fan. (it's a 3.5" 110v with a high CFM). I'll be playing around with this for a couple more days, but so far it looks promising. The vents are also a good idea. I'll update this post as I learn more. -

14 year old Envoy Hot Tub tripping 20 amp breaker

sefanzed replied to sefanzed's topic in Portable Hot Tubs & Spas

Question... Does anyone know the operating temperature range of the Watkin's IQ2020 circuit board? I've been looking for specs online and can't find them anywhere. Thanks -

14 year old Envoy Hot Tub tripping 20 amp breaker

sefanzed replied to sefanzed's topic in Portable Hot Tubs & Spas

I'll have to check the brand, however both the wave master and the other motor get very hot after about 45 minutes. Since the Wavemaster has venting built onto it, (directs heat into the spa cabinet) the area around it presumably doesn't get as hot. The other motor has no provision to redirect the heat it produces. I'm planning to install an axial fan coupled onto the 4" tube that used to connect to the previous motor that was replaced. As I mentioned, I've got to find a 110v connection that energizes when the spa is on. Hopefully that will alleviate the issue to some degree (pun intended). The watkins has it's own proprietary power plugs, but once I find one that's suitable, I can snip it off and install a regular ac plug. -

14 year old Envoy Hot Tub tripping 20 amp breaker

sefanzed replied to sefanzed's topic in Portable Hot Tubs & Spas

Here's another take... I replaced one of the motors with a non-Watkins motor. There's no provision to vent, as there is with the Wavemaster motors. Also, I can confirm the entire cabinet gets very hot after an hour of use... I'm thinking of installing an exhaust fan to vent the cabinet, using the vent that is currently not connected to the new motor. That might solve the issue, however, now the challenge is finding a 110 connection that powers on when the spa is running. I have a couple of unused power connectors, which I assume are for accessories... I'll have to do some testing with a voltmeter to see if they are only powered on when the spa is running... -

14 year old Envoy Hot Tub tripping 20 amp breaker

sefanzed replied to sefanzed's topic in Portable Hot Tubs & Spas

Regarding the shutdown issue. It appears the circuit board is getting overheated. The 2006 Envoy doesn't have an error code for that. After the spa shut down, I opened the equipment compartment and looked into the circuit board enclosure. The board and enclosure were very warm. Reset the breaker and kept the compartment and enclosure open... No problem. So, I'm led to conclude that over the years some component has aged in, causing the logic board to shut down at a lower temperature than it was originally designed to handle. Does anyone have an idea what that component might be? I don't want to replace the entire logic board if there's an alternative. Any ideas? Thanks in advance. -

14 year old Envoy Hot Tub tripping 20 amp breaker

sefanzed replied to sefanzed's topic in Portable Hot Tubs & Spas

No, the shutting off issue is still under investigation. I'm replacing the temp and limit sensors in the heater. We'll see if that addresses anything. I'm approaching this little by little. I'm trying not to throw parts at the spa, but some components are due to be refreshed. I'll let you know where I end up! -

14 year old Envoy Hot Tub tripping 20 amp breaker

sefanzed replied to sefanzed's topic in Portable Hot Tubs & Spas

Hi, Here's a follow up. Replaced the 20 amp CGFI breaker in the sub panel. It's been a day and a half and it hasn't tripped! Safe to say that was the root of the issue. Thanks to all who chimed in! -

14 year old Envoy Hot Tub tripping 20 amp breaker

sefanzed replied to sefanzed's topic in Portable Hot Tubs & Spas

Thanks guys, I'll check both possibilities. I'd like to get another five years out of it if we can. We ready do enjoy having it. I just did a purge/flush (first time in 14 years) in hopes that might alleviate some of the issues, or at least address the efficiency of the plumbing. Unbelievable amount of grease came up, so that at least, is a start. Additionally, my ozonizer is about 2 years old (a Pacifica X-50) so it's probably time to replace also. In California where we're facing chronic water shortages, I don't get to refill the tub 4x a year as recommenced. Instead, I only refill twice a year unless the water gets super-funky. Again, thanks very much for your input. I'll post again when I explore the breakers and the venting issues. -

14 year old Envoy Hot Tub tripping 20 amp breaker

sefanzed replied to sefanzed's topic in Portable Hot Tubs & Spas

The heat in the cabinet is an interesting idea. Is there a sensor inside the spa? Or would it be a thermal breaker on one of the pumps. If the latter is true, wouldn’t only one pump shut down,or would the logic board crash?