-

Posts

112 -

Joined

-

Last visited

-

Days Won

1

Everything posted by rmcderm313

-

Using Slice Valves to Replace/Service a Pump

rmcderm313 replied to rmcderm313's topic in Portable Hot Tubs & Spas

The slice valves didn't work completely. I held a wet vac over the barb where the priming tube was attached and I couldn't seem to empty the volute (the priming tube was pinched and removed). I also held the vac against the bottom of the pump union and let it drip pretty well for 5-7 minutes and it didn't seem to slow down. I'm thinking about picking up a couple of these, which should be able to be screwed into the pump union to seal it while I repair the pump; if I can get them in there quickly. https://www.lowes.com/pd/LASCO-2-in-x-2-in-dia-Plug-PVC-Fitting/3447460 My pump has a 2" inlet and outlet. I think this should screw right into the union and block it just like the pump does. Thoughts? -

ThermoSpa - Pumps 2-5 trip the GFCI

rmcderm313 replied to rmcderm313's topic in Portable Hot Tubs & Spas

OK cool. Thanks for your help and persistence on this with me. I decided to take a chance as I was out of options and before I dug into removing the board. I did this before seeing your last response, my curiosity got the better of me and I decided I didn't really have much to lose. I tried all the suggestions and any way pumps 2-5 are hooked up they trip the GFCI. I even hooked pump 2 to the pump 1 connector and it tripped the GFCI. I hooked everything back up on the spa pac as the wiring diagram suggests and then moved pump 1 through all of the 2-5 connections (not directly to J11 or J12 but to the split cable as factory wired). Pump 1 ran on high speed and didn't blow the GFCI on any of the connections. So.... Either I have 4 bad pumps or there is something in the specs of pumps 2-5 that is too much for the GFCI (I find that a bit hard to believe but I'm open). It's an older hot tub and there was some water damage so 4 bad pumps is not completely out of the question. I think my next step is to pull out one of the 'bad' pumps and overhaul it. New seal/bearings and clean up the shaft and impeller. Then bench test it again and make sure it starts and runs for minute on 120V. If that doesn't 'fix' the issue, I guess I'll buy a new pump and see if I can get that one to run. Can anyone think of why a pump would fire up and start to spin, but then have enough of an issue to trip the GFCI? Would a pump in this condition spin on 120v? Any recommendations on a solid test approach for a pump other than just trying it? Thanks CanadianSpaTech for your guidance thus far. It's awesome that you offer your knowledge like this, it makes a big difference to newbie DIY guys like me. I will update on progress. Rob -

ThermoSpa - Pumps 2-5 trip the GFCI

rmcderm313 replied to rmcderm313's topic in Portable Hot Tubs & Spas

Cool I'll try that next. If the GFCI is still tripping would there be any harm in trying the working pump 1 on J11 or J12 to see if a known good pump trips it? Same volts and amps. Only difference I can see is pump 1 has .5 less HP and is 2-speed. Thanks, Rob -

ThermoSpa - Pumps 2-5 trip the GFCI

rmcderm313 replied to rmcderm313's topic in Portable Hot Tubs & Spas

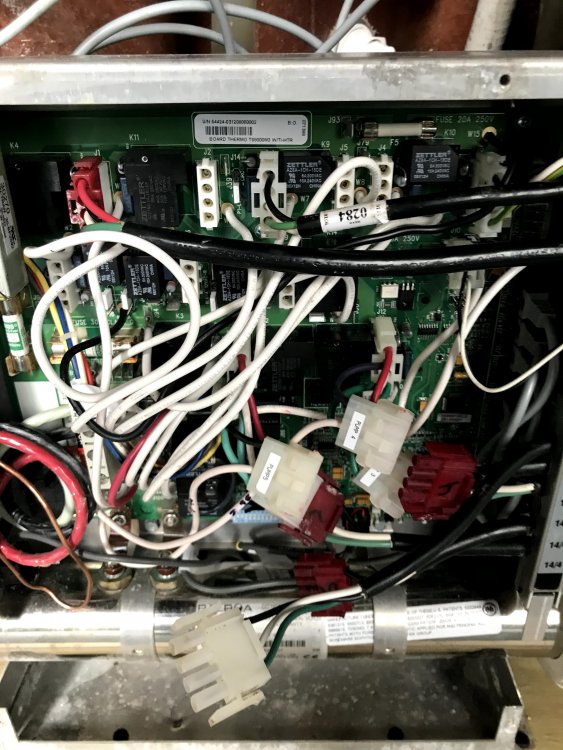

Thanks. If any specific part would help just let me know and I'll get a better picture. Some of these were taking while I was testing so some connections are off, but everything started as documented in the wiring diagram above. Thanks a lot for your continued assistance! Rob -

ThermoSpa - Pumps 2-5 trip the GFCI

rmcderm313 replied to rmcderm313's topic in Portable Hot Tubs & Spas

Can I hook a pump directly to J11 or J12 without using the spliiter cable? -

ThermoSpa - Pumps 2-5 trip the GFCI

rmcderm313 replied to rmcderm313's topic in Portable Hot Tubs & Spas

Thanks CanadianSpaTech Here are my actions and results: At the start of each test I ran the following steps just to be sure nothing had stopped working: Pump 1 low-high-off - all successful Blower on-off - successful Light on-off - successful All working items turned off Test 1 J11 connected J12 disconnected Pump 4 to J95 disconnected Pump 5 to J46 disconnected Pump 2 on - blows GFCI Test 2 J12 connected J11 disconnected Pump 5 to J46 disconnected Pump 4 to J95 disconnected Pump 3 on - blows GFCI Test 3 (just to be thorough) W14 to J57 disconnected (connects J11 to 240v) J12 connected J11 disconnected Pump 5 to J46 disconnected Pump 4 to J95 disconnected Pump 3 on - blows GFCI Test 4 (just to be thorough) W10 to J61 disconnected (connects J12 to 240v) J11 connected J12 disconnected Pump 4 to J95 disconnected Pump 5 to J46 disconnected Pump 2 on - blows GFCI I also tried swapping out different pumps connected to the 1 active connection, that way if pumps 2 and 3 are coincidentally bad, it won’t mislead the results, Essentially everything I tried tripped the GFCI as soon as I started the ‘active’ pump, no matter how isolated the pump connection was. New Info, the last test I did was targeting pump 4 and when it tripped the GFCI I saw a wisp of smoke come out of the motor. I had never seen that before and I’m not sure which might be causing the other. Keep in mind that I did bench test all of these pumps with 120V and the volute off, and they all turned. I should also mention (I’m new at this keep in mind) that I have not secured these pumps down. I was waiting to see how everything worked before locking everything down. During this episode with pump 4 it bucked pretty violently when it started before tripping the GFCI. Is it ill-advised to leave the pumps not-screwed down to the frame? I’m at a loss. Any thoughts on connecting one of these ‘bad’ pumps to the pump 1 connection and seeing if it starts? Or connecting pump 1 to one of these ‘bad’ connections? One other thing, there is a red wire going from 240v J55 to W3. It’s not documented on the wiring diagram. It’s shown but not mentioned what it’s for. It’s the only connection I haven’t tried removing. Any and all help would be appreciated. Thanks, Rob -

Can anyone tell me what this control is? It connects to a 2 way union (second picture). One end comes out to an open pipe right over my spa pac, and the other goes somewhere under the tub. Seems like a bad place to have an open pipe if water can get in there. Any thoughts?

-

ThermoSpa - Pumps 2-5 trip the GFCI

rmcderm313 replied to rmcderm313's topic in Portable Hot Tubs & Spas

Thanks CanadianSpaTech, I understand all of the activities you describe, but what should I do as the test for each step? Keeping in mind that the GFCI only trips when I start one of the pumps 2-5? I can leave everything connected and the GFCI is fine until I try and start a pump. When J11 is disconnected should I try starting one of the pumps 3 or 4 and vice versa? I do not have an ozone or a mister but I do have a diverter valve that controls a wave pump. I've left the wave pump and diverter disconnected the whole time as I know the diverter is seized. Thanks for the reply. Rob -

Hi All, Newbie spa repair question.. Can I use slice the slice valves on either side of a pump to replace it when the tub is full? I believe this is what they are there for but I'm wondering about the effectiveness stopping water flow when the tub is full? My tub is inside, on a concrete slab but I don't really want a ton of water coming out. I can handle the water inside the volute if the slice valves really do hold, but if they are just meant to stop some of the water I'll opt to drain the tub instead. If they are pretty effective I'll give it a shot. I also do understand that a valve's performance is only as good as it's condition so I'll take responses with that context. Thank you. Rob

-

ThermoSpa - Pumps 2-5 trip the GFCI

rmcderm313 replied to rmcderm313's topic in Portable Hot Tubs & Spas

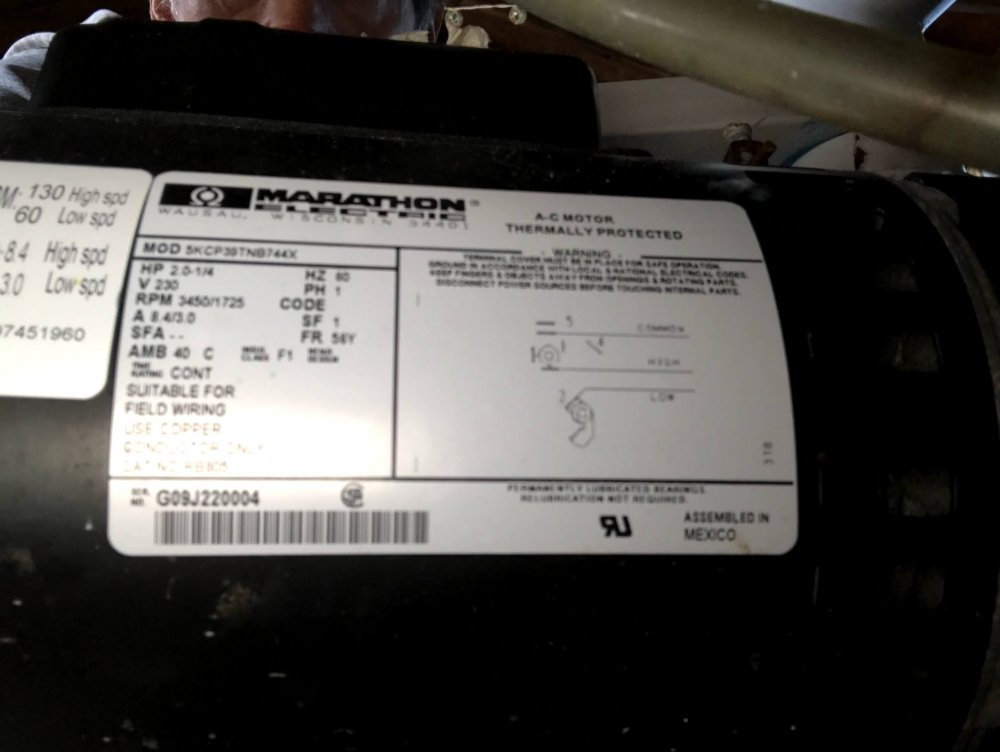

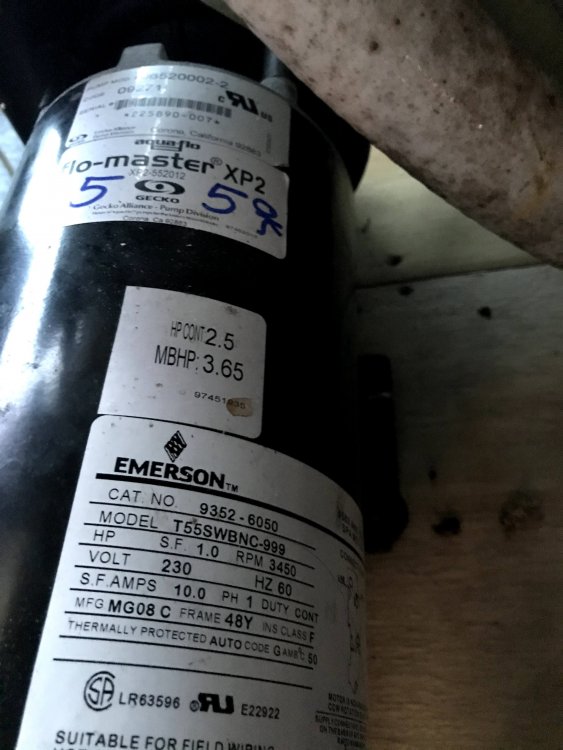

Hi All, As a first troubleshooting step I'd like to isolate the issue to a single pump if possible to start with. Would it be safe to swap the connections on the spa pac for pumps 1 and 2 (for example)? Then if pump 1 continues to run without tripping the GFCI when I start it by pressing the pump 2 button, and/or if pump 2 continues to trip the GFCI when I start it by pressing the pump 1 button, I'll know the issue is directly related to pump 2 and not a wiring connection on the board. If the behavior changes based on where the pumps are connected to the board I have a different issue. The specs for the 2 kinds of pumps in the tub are below. I'm thinking that the only thing that matters from the standpoint of where the pump is connected to the board is the voltage. Since both pumps are 230 volts I don't think the board will care which one is connected to the pump 1 (J1) connection and which one is connected to the pump 2 connection (J11). But I don't want to do any damage to my board and/or a pump by connecting them to a board input where I shouldn't. Does this sound like a safe and sound troubleshooting step? Speed HP Volts Hz Amps Frame RPM Pumps 2-5 06520002-2 Aqua-flo Flo-master XP2 1 2.5HP 230 60 10 48Y 3450 Pump 1 06620003-2 Aqua-flo Flo-master XP2 2 2.0HP 230 60 8.4/3.0 54Y 3450/1725 Thanks, Rob -

ThermoSpa - Pumps 2-5 trip the GFCI

rmcderm313 replied to rmcderm313's topic in Portable Hot Tubs & Spas

-

ThermoSpa - Pumps 2-5 trip the GFCI

rmcderm313 replied to rmcderm313's topic in Portable Hot Tubs & Spas

-

Hi All, I've just inherited a TheroSpa Manhattan. It's got a Balboa board/heater and 6 pumps, the circ pump and pumps 1-5 and a blower. I can start the tub fine, the circ pump kicks on fine. Pump 1 runs on both low and high speed fine. The blower runs fine. When I try and start any of pumps 2-5, they begin to kick on and then trip the GFCI. Pumps 2-5 are all one speed. Pump 1 is 2 speed. Pump 1 connects to a dedicated connection on the board, pumps 2 and 5 and pumps 3 and 4 connect to shared connections with 'Y' cables. The diagram on the inside of the spa pac matches the way things are hooked up. I guess it's possible that all 4 of these pumps are having issues but it seems unlikely. Before I go and replace one pump, I'd like to hear some opinions on whether something else could be going on. Is it possible that the board could be faulty? If that were the case it also seems unlikely that both of these connections went bad. The pumps do start to spin and move water, but then the GFCI trips. Any thoughts on what might be going on? Thanks, Rob