vikingGoalie

Members-

Posts

21 -

Joined

-

Last visited

-

Days Won

2

vikingGoalie last won the day on September 30 2020

vikingGoalie had the most liked content!

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

vikingGoalie's Achievements

Junior Member (2/5)

4

Reputation

-

so unfortunately i do have an update. motor 1 got finicky again. so this time i took it out (i'm pretty quick at this now, lol) and my slice gates work well. I took it out and used 600 grit sandpaper and really cleaned it. After doing so, i found out that on 110v i could start and stop the motor at will with a switch. Put it back in the tub and it worked flawlessly for 3 days, cycling on and off as the system called for heat (it's doubles as the circulation pump). Today i had to nudge it again. grr. the start windings are 100% fine. I'm thinking the contact switch for the start circuit that the copper is just that worn down (it's copper plating). i was being careful with the sandpaper to just clean it and not take off any plating though that's tricky to be sure of. Thing is I'm now such that I can literally yank the motor out and have it on my bench in literally 5-10 minutes it took me about an hour to take the motor out, take it apart, sand the contacts and put it back in while drinking my morning coffee. So debating if i just replace that switch/contact piece (if i can find it) or bite the bullet and get a motor. Thing is the motor isn't *that* much I found it for $250 with free shipping and that includes the wet end (which I don't need). but if you guys haven't noticed I tend to fix things and take a little pride in that Thing is the hot tub isn't all that annoying right now to manage as is as it takes a very slight twist with a wrench and motor fires right up. and i'm talking less then a 1/4 of a rotation at most and it fires right up. I will get this resolved one way or the other. As it stands I'm $60 (impellers and seals) in on this tub and my time fixing this motor. Which is still not a bad deal

-

so final update (i hope) on the motor(s). so we rather enjoyed the hot tub the other night. sadly i turned it off knowing that it wouldn't turn on without help which i tried after i turned it off and of course was the case. so next day, me being me, I decide to pull the motor out again. Just to be 100% sure, I found a neighbor who has a capacitor tester (i'll get one but needed one now). All THREE capacitor's tested fine and within spec. So I regret I didn't take pictures of this but will try to describe this. So the start capacitor's job is to give a jolt to the motor to get it going, once the motor is going it needs to jump out of circuit because if it gets continous charge it will burn up/out. The way this is accomplished is generally the same in electric motors, a contact is made at rest. Once the motor starts spinning the centrifugal force is applied via a switch to disconnect the circuit. Thing is in my head I know an electric motor is a very simple heavy duty beast. Capacitor's wear out, bearings might need replaced but the rest almost never wears out. So tearing the motor apart. There is a copper disk, and a v shaped copper plate on a spring that makes contact with it. when the motor gets spinning the switch makes it lose contact. So I did two things. I first off cleaned the contact areas up very gently with my trusty fingernail and paper (i kid you not) u don't want to use sandpaper here to abrasive. I then made triple sure that when I re-assembled the motor that it was in contact with this disk as if you are not careful you can make it so this doesn't happen. So I'm on my bench, first test at 110v i flip the switch and motor instantly starts up! Second+ tests it doesn't start. BUT I tell myself this is exactly what the good motor did it fired up one time and never again. So then I go out to my spa with the motor (wet end is not attached) and plug it into the spa panel so I can give it the proper voltage. It fires right up, both low and high work. I turned it off and on 4 times worked each time. So tomorrow I'm putting it back in the tub and I think I'm in business now. thx everyone for the help/tips and I hope this thread helps someone else.

-

yea i reluctantly plan on using the tub tonight and then turning it off and letting it cool down. though i've watched the motor it tries for a few seconds then clicks off (thermal protection) not that I'd want to leave it in that state for any length of time. I'm just kinda ticked that I tried 3 different start capacitor's same result. but it's gotta be that if it was the run capacitor it wouldn't run, and it runs like a champ once it starts turning. i could just turn the jets on and leave em on for the night but yea i will get this fixed right it's just i put this much work in and was this close i was in a "i'm getting in my frickin hot tub" frame of mind tonight... it is heating up nicely as i'm up to 92 now so the heater works pretty well.

-

oh just gotta reply, heater is working. as tub has come up 4 degrees since i last posted.

-

so with start capacitor in hand i went by a local hot tub place because the guy there is really helpful and if i could give him some business i'm fine with that. Told him what was going on and he agreed that it's probably the start capacitor, he had 2 dead motors he had pulled off somewhere and he promptly handed me two start capacitors and said give these a try, and didn't want any $$$ from me. sweet. So i go back and put teh first one in, same thing. Hum, no turning. Put the second one in, Hum, no turning. Both of these capacitors are rated higher then the one they replaced. (ok to go higher) So then I decided to play with electricity (don't do this at home). I left the cover off the motor, and when the control box called for it to start i used the slotted end where you can put your screwdriver to turn the shaft and turned the shaft just slightly and it fired right up. So it's running now, on circulation mode and it goes to level 2 when i call for jets on that motor so it is switching between low/high. I'm just gonna give the tub a while and see if my heater actually works 😐 If not I'll pull the element out and replace it. But even the local hot tub guy was kinda like I'd just turn it on and see if it works rather then pulling the element to do a resistance test. Fingers crossed... I dunno if the motor kicks off if it will come back on but I'll cross that bridge when i get there. It is possible i have 3 bad start capacitors as the other 2 came out of "bad" motors. Really need to get a capacitor tester... (oh and I was gonna try and pull the capacitor from the motor that starts right up but it's the devil to get at with the motor in the tub)

-

Does this sound like a pump is rusted or frozen?

vikingGoalie replied to matrophy's topic in Portable Hot Tubs & Spas

i would look at the frozen motors thread i started. my journey of discovery has taught me that motors that sit for a while are problems. fixable problems if you are handy it's definitely a diy'er thing. if you rather have your weekend for other pursuits then fixable by someone else. -

So both motors back in the Hot Tub. Motor 2, runs like a champ on both speeds. Motor 1, humms. [insert swear word here] But i won't be dissuaded, i know motor 1 works I had it working on the bench but I had to give it a twist to get it going. So... when i have light tomorrow it's gotta be something with the start capacitor I just assumed it was "ok" as I can't effectively test it. So either it's bad, or i was a dumb ass and there is a wire not connected to it. I'm kinda hoping for dumb ass, but start capacitor is an easy change so not too worried. The only thing that sucks is that this control board does support a seperate circulation pump, but it is configured such that pump 1 is the circulation pump. So no circulation, the heat isn't gonna do anything so I think the heater works but won't know for sure until i have flow from pump 1. any hoo this will work, it is a quest to make the Hot Tub work now

-

p.s. i hate the usps took forever to get the parts and then i get them in the evening. but plan on having the motors ready to put in tomorrow over lunch (i work from home)

-

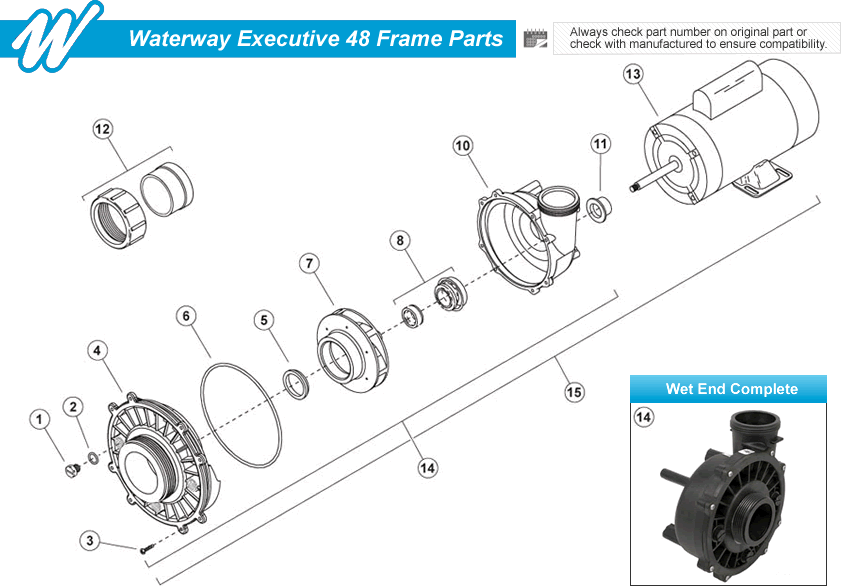

so just got the parts, putting the stuff back together and i realized that the slinger piece is a bit of an oddity. if you look at the diagram it's number 11. so it looks to me like it is between the volute and the motor. but I know for a fact it wasn't when I took it apart. it was on the inside of the volute sitting down in the hole below the seal. thing is i went and watched this guy (good video for anyone reparing a motor/wetend) he is actually taking apart a waterway wet end, and I see the slinger piece fall out when he takes it off but he does not put another one in, and he is the "spa guy". so now i'm debating if i put this slinger piece in at all, and if i do where exactly as in his video the piece that falls out is between the motor and volute, i know in my case both pumps had one and they were not between the motor and the volute. thoughts?

-

grr. impeller parts didn't come yet, should be here tomorrow. oh just btw. I talked to a guy who runs a hot tub store and does service. he told me that it's normal that 240v motors to not start up like that when wired to 120v. Which if you think about it makes sense, the start capacitor says right on it that it's 250v, so quite possible it won't charge up enough to kick the motor over when wired to 120v. i spent some time today constructing steps to the hot tub. i'll post back once i have the motors in.

-

lol. i mean it was really hard to take this motor out, hire a professional ! so i wired it to low, don't wire it to the high it won't quite run right and try to draw to much amps. (i tried it for a brief sec) i think high needs both phases where as low just draws on one leg i.e. 110. i might be completely wrong as i didn't google that lol. but it makes sense in my head anyway. I thought that myself, the 240vac might be what it needs, i guess it doesn't hurt anything to try that but i'll have to wait until tomorrow when it's light out. I watched a youtube though where a guy did this and the motor started right up so I'm thinking it's most likely the capacitor, but. but. it is both motors doing this. The first motor actually started up the first time without help, but refused to do so any attempt there after. so the voltage thing might be it. dunno. stay tuned on that i'll try it. It would be nice if I could just test theses but while my harbor freight multimeter has a capacitor setting but it is a retarded you gotta plug the capacitor in and it won't go up very high anyway. so a 2 prong capacitor you can plug in but normal bigger capacitors like on a motor it's no good for.

-

so i know this is kinda the thread that keeps going but i am on a mission to do this myself. so i took the advice and wired up a cord so i could run the motor on 110v. so I think the start capacitor's on both motors are probably shot. The motor doesn't rotate super easily but not hard at all by hand. but this is what goes on. off to find my multimeter and see if i can discern if the capacitor's are bad.... 20200924_174939.mp4

-

this: https://www.poolzoom.com/slinger.html the impeller piece says 2HP in the center so figure I just get the same, even though the one motor is 3HP. Once again thx for the help on this. I think I'm gonna live dangerously and not mess with the bearings right now. Honestly it wasn't that hard to take these motors out and apart so if I have to deal with that down the road I will. The only real difficult part was the one impeller took significant force to spin off. (thank you oil filter wrench)

-

only thing with running the motor is i don't have a 220 line out in my workshop. I'm still looking at prices but seems like this: https://www.poolzoom.com/3-hp-impeller.html?gclid=CjwKCAjw-5v7BRAmEiwAJ3DpuLnfNJ9rzD5X3oZaTOiShNUTTlHfAm3A8OBmkYSod5NVHKdkqyTcYRoCAxYQAvD_BwE is a pretty reasonable deal, can get the impeller and other bits i need for roughly $38 per motor. do i need more then the seal assembly, impeller piece and some silicon sealent? (I through the slinger piece in there as well as they are pretty cheap, but i do have those from the old impellers). i'll go watch a youtube or two on this part. anyhoo thx again everyone.

-

so my plan right now is to deal with the rust on the motor shafts, I have 3-1 oil on the shafts right now and tomorrow gonna work on getting the rust off the shafts of the motors first with a brass brush but i have some sand paper i use for knives that should work well as well. Get the right parts and put it all back together. Thankfully I believe the bearings of the motors are fine, they spin very easily. The one stator does have a bit of rust on the stator part but not sure if I should deal with that or just leave well enough alone there. Anyhoo, i'm pretty hard core diy on just about everything around the house but this is my first tearing a spa motor apart thx for help! (oh don't mind the messy work bench, i had tried the strap wrench first and that just wouldn't turn it, I used these: https://www.walmart.com/ip/Hyper-Tough-Oil-Filter-Wrench-63-5mm-116mm-Model-1208/55524395 to turn the impeller off and they work super well for that.