chrispomeroy

Members-

Posts

18 -

Joined

-

Last visited

Profile Information

-

Location

Lake Tahoe, CA

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

chrispomeroy's Achievements

Junior Member (2/5)

0

Reputation

-

I just bought this kit after frying my board recently: https://www.spadepot.com/Balboa-BP7-Spa-Control-Kit-P3185 It hasn't arrived here yet so I don't have experience with it yet. Here's a video of swapping it in and replacing a completely different model. https://www.youtube.com/watch?v=8q96124Dujc

-

Since I already have a Gecko (branded as SpaGuts) control board it probably would have made sense to buy a new Gecko in.ye or in.xe; that way I could reuse my top side controls, pump cables, and my existing Wi-Fi adapter. A few reasons made me switch to a Balboa BP7 instead: Pretty much all of the Geckos I found in their mid range category support both 220V 4kW and 5.5kW --- but --- come equipped with a 4kW heater. I couldn't find any online that had the 5.5kW for a reasonable price. Also Gecko seems to be only sold by obscure online stores. I didn't want the hassle of trying to find the right 5.5kW heater element and replacing the 4kW without blowing something up. SpaDepot.com carries a Balboa BP7 that they configure for customers, and have always shown responsive support when I call/email them. Plus I could buy my PVC fittings from them at the same time. The Balboa kit included the topside control and cables for $518, so it felt like it came with the package. I'll sell the kn.200 Gecko topside control. I found a Balboa wi-fi module for $160 on ebay which was a fair price. The Balboa unit acts as its own Wi-Fi endpoint making it simpler to connect to one of my access points. With the Gecko unit - its a 2 piece system using a hub to be installed in an Ethernet port and for my setup this is much further away from the tub than my nearest Access Point. During high snowfall years, I would get intermittent signal between the two Gecko devices.

-

Also wondering how the model numbers and model names work with Balboa (and other brands more generally). For example when Balboa sells their "BP-100" in 4-5 different versions with different configurations (number of pumps enabled, voltage, etc) all of these "submodels" are simply a convenience for the installer and not really a different model correct? Meaning - the top level product "BP-100" is the same and can be reconfigured using wiring, jumpers, or DIP switches to get whatever config desired? I found a BP-100 online equipped with the 4kW heater, but the model supports 4kW and 5.5kW heaters via different heating elements. Is this configurable by me if I buy the right element? Or are certain sub models (e.g. BP-100G1, vs BP-100G2 etc) fixed to a certain heating output? Last question - some of these spa pack bundles include either the TP200T or TP200W topside control. Both are 4 button controls, just one is designed for a 2-pump system vs 1 pump. (difference being the TP200W has a temperature up and down button) Are these the same controls simply with a different decal on top or are they actually different mechanical parts? I'm guessing these two topside controls are the same mechanical part and use a different decal where each of the 4 buttons may play a different role depending on the number of pumps and other accessories enabled in the configuration but wanted to check.

-

Seems like the melted heater leg must have shorted somehow. Could water be running over the tub and into the enclosure (this just happened to me 🤣). Is it possible the sand/dust in your area has iron in it and its collecting in the enclosure somehow? Could it be these tiny spaces with so much equipment packed in, combined with high set temp, and high outdoor temp, is causing thermal distortion and shorting out the board? Throwing out some more ideas.

-

Looking for recommendations of a new spa pack. My requirements are Reliable / simple design Current model (not old stock) water resistant (as much as possible) supports 1 2-speed pump can be controlled by Wi-Fi 5.5kW heater Runs on 50 amp 240V I do not use a blower, multiple pumps / circ pump, ozonator, lights, or any other features. Right now I am looking at the Balboa BP100 with Wi-Fi Adapter. Seems like the Balboa BP 7 is also very common but ideally I do not need a control board that supports 4 pumps. Is there any downside to the Balboa BP100 for my application versus the BP7, BP501, or BP2000 or another model?

-

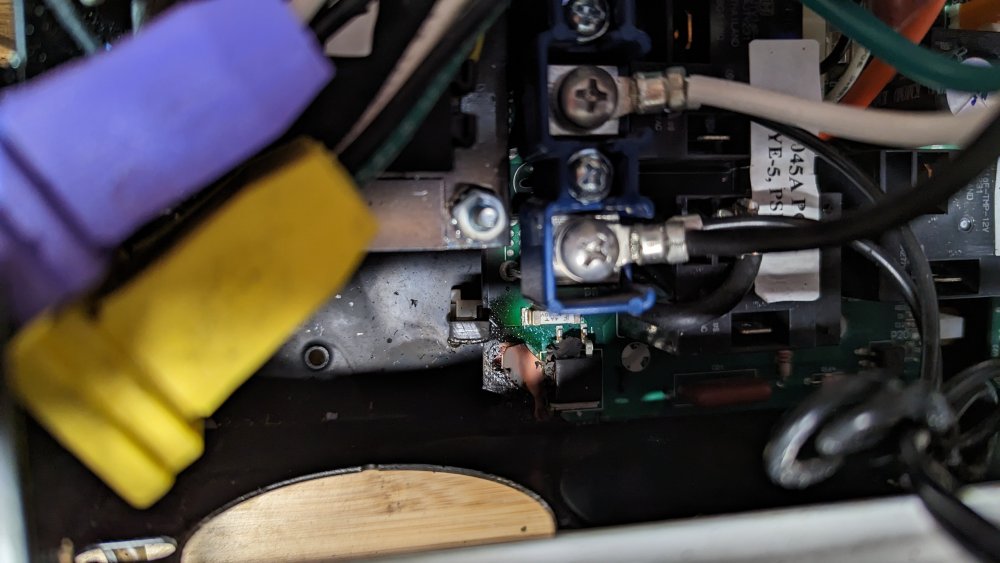

Better pic below close up after I removed the heater tube. Seems like the enclosure is too small for the circuit board. Even if there were perhaps drain holes in the back of the enclosure, the surface tension of water lends itself to bridge the gap if a small bit of water would collect here. I also understand there is a circuit board clip out of place, but thecircuit board is still centered in the enclosure, and there's no room to move it any higher.

-

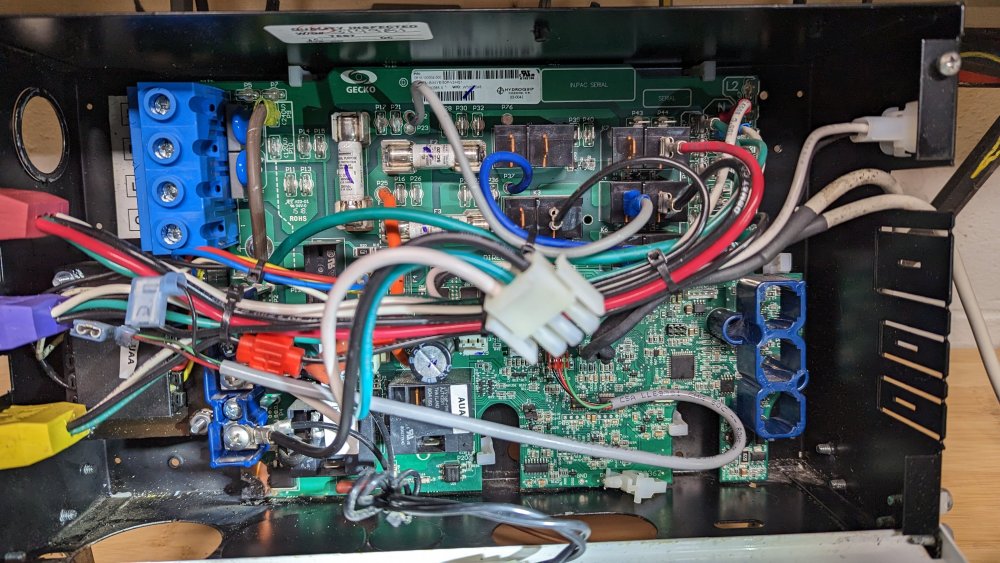

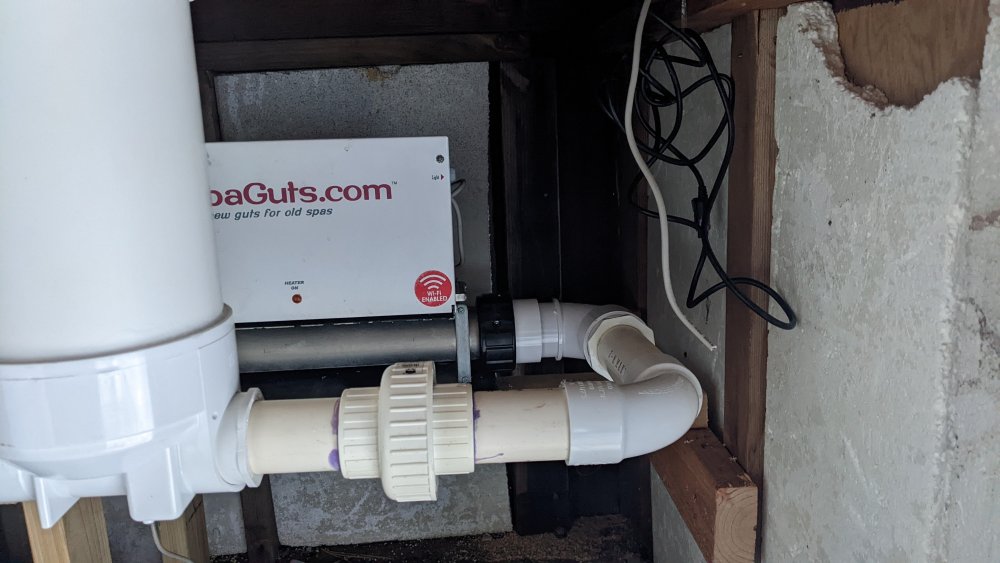

The cursed hot tub saga continues: I have a leak in the pump AND just fried my controller board. Backstory: Soon after my last post I was able to get everything operational again with a new GFCI breaker. However I noticed the pump wet end was leaking. I decided to replace the main shaft seal and O-ring seal. The shaft seal looked at 50% life left and probably didn't need to be replaced but I did it anyways. The wet end unfortunately still leaked once back together, at the lowest bolt hole. I actually slowed the leak down to an intermittent drip by loosening all 4 bolts that hold the wet end together. It appears these are really only supposed to be finger tight? Next I installed some 1" foam board insulation in the cabinet. Filled the tub and all was good (I tried to forget about the wet end drip/leak). Last weekend the tub was a bit overfilled and some water overflowed. This has never caused any issue in the past. But -- this time due to the piece of foam board insulation I installed, the water was unfortunately channeled to drip directly on top of the control board enclosure. (remember this is an old Spa that has the controls and pump plumbed below it under my deck) The water then dripped directly onto the main board enclosure and pooled at the bottom just enough to create a "puddle" only a few milimeters deep which caused an electrical arc within the lower left corner of the control board. What a disaster! Going forward I don't think i will ever buy a spa controller that is not sealed from water entering from the top. Even more frustrating was seeing how little clearance there was between the enclosure and circuit board. If the enclosure was just 5mm bigger, the water wouldn't have created the electrical arc. It was a Gecko control board packaged and sold by Spaguts.com. I'm now shopping for a new heater/controller combination. Pics of the damage below:

-

Thanks RD, yeah it's been a while since I wired a subpanel and forgot how it all worked. Thanks for clarifying. Bought a new GFCI breaker. Checked all my wiring again, the subpanel grounds. Disconnected the pump and heater, flipped the breaker and it tripped again after 3 seconds. Looks like I bought a new $200 breaker for no reason... Damn, it's not the breaker. I was left with thinking I had to disconnect the controller again and bring it inside to inspect everything closely. That would be a huge pain. Then I got to wondering, since the controller is starting up for 3 seconds before tripping, perhaps there is some circuitry that will short out the electrical supply in the event something is damaged, a fuse is blown, or something is plugged in wrong. Something that is outside the current supply path perhaps. I noticed on the board I had left a 4pin plug disconnected which is a combined heater high limit sensor and the water temp sensor. Plugged it back in, flipped the breaker, and it stayed on. It continued working even after I added the pump and heater. I'm pretty baffled why this would be designed in this way. I can see the board but wanting to power the pump or heater if it has not temp input, but why short circuit itself? Seems like a little overly cautious and could send an installer or owner like myself down so many confusing diagnostic paths. Is this common?

-

I just re-confirmed wiring was set up correctly. (L1,N,L2 spa leads go directly to GFCI breaker, Feeder line connects to 4 subpanel bus bars, and GFCI N pigtail goes to Neutral bar. Then, tested continuity across the Board terminal Ground and Neutral and there was continuity. hmm. I removed the spa L1 & L2 leads from the breaker, and still have continuity. Removed spa Neutral lead from breaker - no continuity. With the breaker and spa leads removed from the subpanel, I tested for continuity from panel Neutral bar to panel Ground bar and it has no continuity, so I think the panel and internal bus bars are correctly isolated. I can't really understand how there could be continuity from Neutral to Ground through the breaker. Even with an internal short, the breaker does not have a path to ground as it just connects to L1,L2,and isolated N bar, but I ordered a new breaker to hopefully fix the problem.

-

Cemented all PVC and reassembled everything but now my GFCI subpanel breaker trips when I turn the breaker to ON, after about 3 seconds. I hear the spa pack click twice, the the board LED turns on, and the heater LED. Pump does not start. Heater element measures 9.8 Ohms across element. Next, I disconnected the lines from the GFCI subpanel breaker to the pack, it does not trip with no load. Next, I disconnected the Heater and Pump, (No ozone, no blower, no lights, or other pumps are in use in this system) - breaker still trips after 3 seconds. Besides re-checking all my wiring, what would be my next diagnostic step? Replace the 50amp GFCI breaker? Any other electrical-related common issue that could happen after a freeze-up? Could the fault that occurred which tripped the breaker due to a short from melting snow have broken the breaker? It's possible, but not likely, water got into the subpanel during the snowstorm, but everything is bone dry now.

-

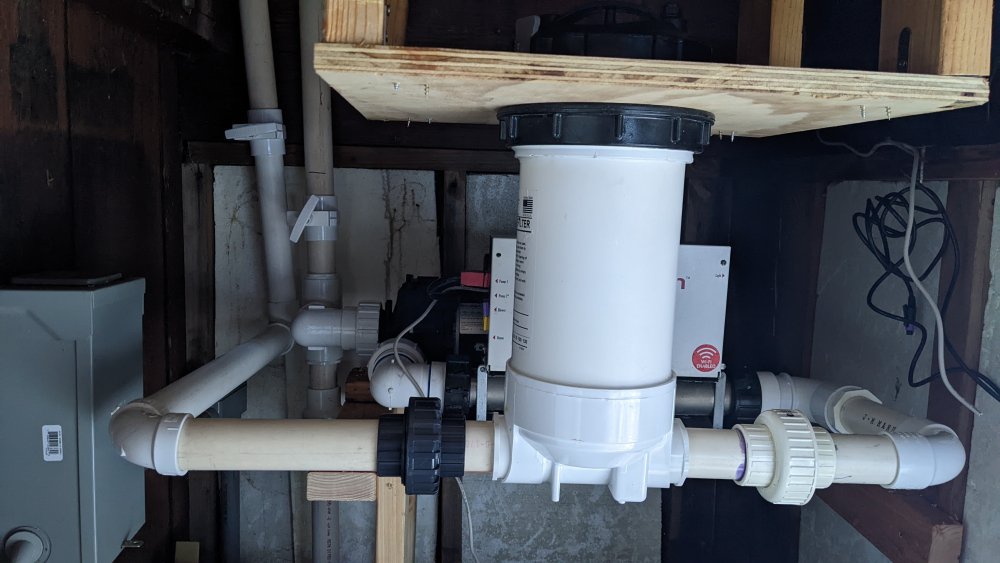

I decided to rebuild the system in the same place. All my plumbing is roughed in but not cemented yet and wanted to get an opinion on the layout. New design: All plumbing is much higher now so when I insulate this "control room" it should retain heat better. I installed a much nicer drain valve (blue handle in pic 2) which is 1.5" so should help drain the tub much faster and easier. The new filter is larger, a top-load screw cap design, and has a spring bypass valve. It should be easier to operate than the previous bottom loader. There's just enough clearance to R&R the filter. New gate valves and almost all new PVC. Things left to do: The pump platform is not level - I will be fixing that. I will be adding some rubber mats under the pump & controller. I will add insulation around everything. I have to move the breaker box up higher to get it out of the way of the plumbing. BIG QUESTION: I read somewhere you want the pump assembly to be the lowest point in the system. The way I have this system rough plumbed in today the return pipe is about 1" lower. Will this cause a problem when refilling? I can lower the pump/controller 1-2" if this is best practice to keep it the lowest point in the system.

-

Thanks - great idea! Really worried about this. I was able to get the water to flow out of the filter lines, but when I closed the gate valve on this side I could not get water to drain from the blower side. I believe all the lines from the tub outward are thawed out, but the internal blower lines may be frozen solid. I really hope I don't have to pull off the wooden trim work (its the slat and stainless band style) so it would be a huge pain in the ass in the winter to fix a burst line... This is already in the works. I just bought a screw top filter that I'm planning to hang from the deck rafter by building a plywood bracket to hold it, and not have to deal with the flimsy pipe hanger and having gallons of water drop whenevr i unscrew to clean the filter. I also thought about deck flush mounting it, but that would mean I would need to run the pipes outside of the box (as the spa is much wider than the box). Still thinking about it.. The other crazy idea I had was spinning the tub 90 degrees and pointing the plumbing outlets where I have more deck space, and building a box with a hinged lid I can mount everything in that would double as a step (and flush mounting the filter in it). It could be tucked against the spa wall so heat would transfer between. A lot more work (since the spa is round), and probably a summer project, but something I have thought about. This would save a lot of hassle going under the deck to do any repairs.