csdude55

Members-

Posts

20 -

Joined

-

Last visited

Everything posted by csdude55

-

Leveling a hot tub when the cement slab isn't level

csdude55 replied to csdude55's topic in Portable Hot Tubs & Spas

Thanks for all of the advice! I'm running out of time and it's about to be cold weather, so this will probably be pushed off until April 😕 I hate that because it's physically uncomfortable the way it is, but there's just not enough time in the day! -

Leveling a hot tub when the cement slab isn't level

csdude55 replied to csdude55's topic in Portable Hot Tubs & Spas

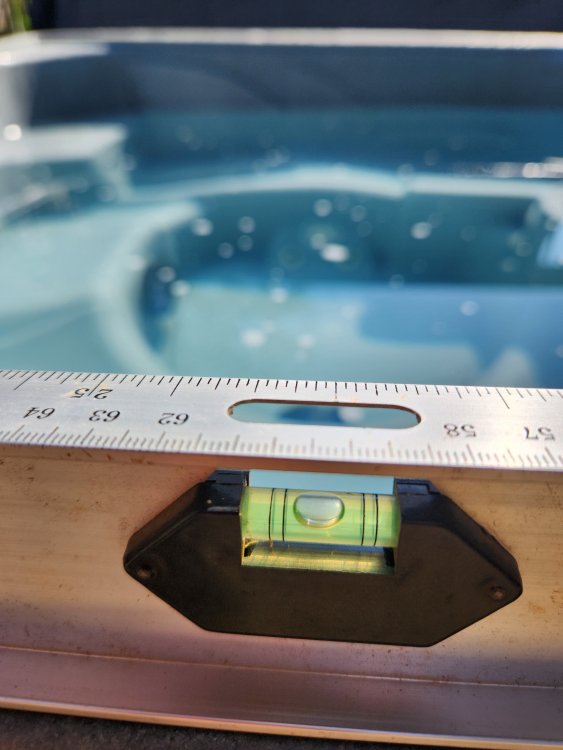

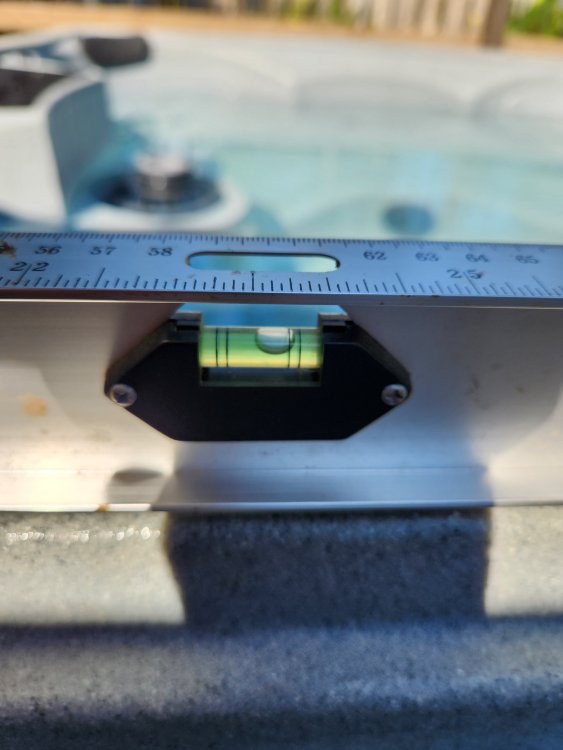

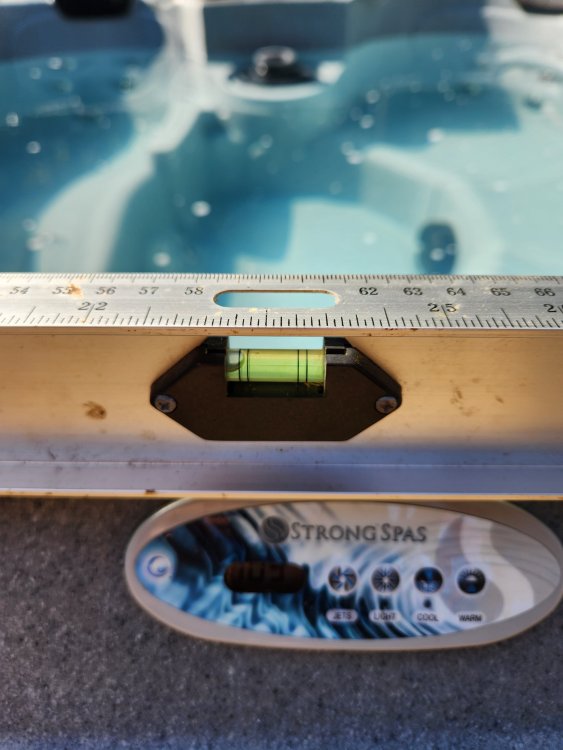

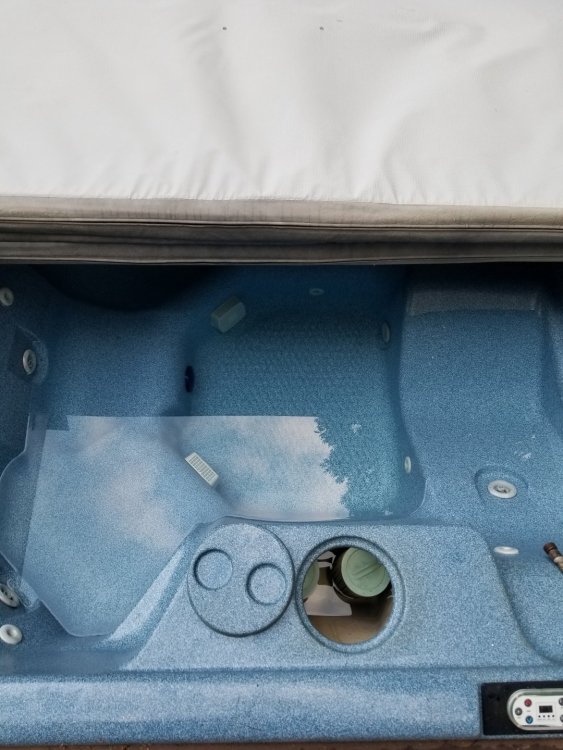

Sorry for the late reply! I just now found the emails in my spam folder, I didn't know anyone had replied 😕 I'm including a pic from above, you can see the water level on the right versus left. I had another pic that showed it more clearly, but I keep getting an error while uploading it 😕 I'm also including 4 pics, showing the level on each side. The side with the control pad is the most out of level, and the opposite side is the next worst. -

When I bought my house it had a hot tub on a cement slab. I could tell that it wasn't quite level, though, which I HOPED was due to the fact that there was a wet and rotted piece of plywood underneath! Today I had a new hot tub installed, and... I was wrong. The cement slab isn't level 😕 I'd bet pennies to dollars that they didn't put gravel or anything underneath, they just poured it straight on the ground. Obviously the right move would be to jackhammer the old slab out and have it done right, but I honestly don't have the money to do it. So I'm thinking... less expensive. I'm thinking that I can drain the hot tub, lift it up, then put a frame around the cement slab and add pea gravel or leveling sand to level it up. Thoughts? If that's acceptable, how do I lower the 500lb hot tub on top of the freshly leveled sand without messing it up?

-

I haven't soldered anything in years (decades, honestly), but as long as my iron hasn't rusted or something then I should be able to swing it. Might actually be fun 🙂 I'm already $200 deep (for the used heater), and it's REAL hard to come up with another $500+ for something that I use like 5 times a year. But I can swing $100, I think. Well, that plus the cost of new solder, I guess. It's raining now, so I'll try to pull it out on Tuesday and see what I see. Labeling everything so that I can put it back together is probably going to be the most tedious part, I think. Either way, I'll post back with updates. Thanks for all the help!

-

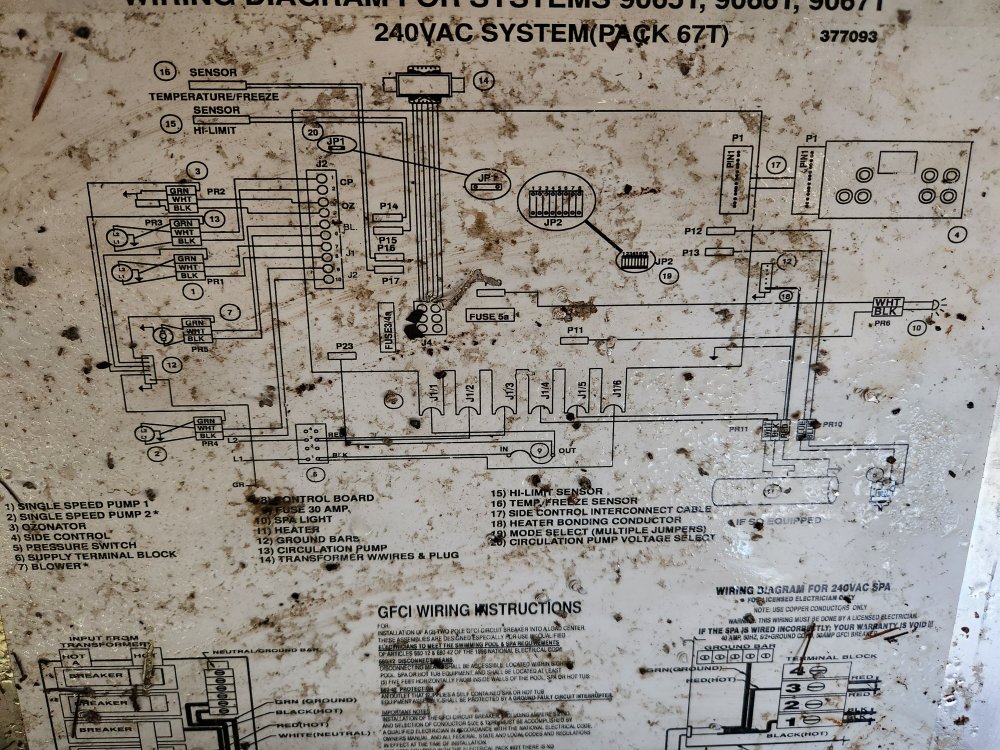

This picture is just the top of the hot tub itself, so you can kind of see what I have on the deck. The power is off in that photo, and that's a garden house filling it up inside of the filter chamber. This is the topside control. That's not original, several years ago I had to replace the main board and replaced the topside control, too. Here is the rebuilt heater that I purchased locally. You'll see that the seals didn't quite line up so it was leaking from the top, but I fixed it after taking the photo. The hose in the bottom right of that photo leads to the circulation pump that's maybe 8" away from the heater. This is the main board. The black port you see in the bottom right goes to the heater. I've checked all of the fuses and they seem fine. The only thing that doesn't look perfect (to me) is a capacitor in the middle-right (SouthWest of the black line to Heater Line-1) that has a little electrolytic gel on the board, but that looks pretty old so I don't think it's the source of the problem. This is the wiring diagram that's on the inside cover to the main board. Today I used an air compressor at 15lbs to blow out behind the board, hoping that there might be something behind it that's causing a short. Then I turned on the breaker. Measuring voltage from the black wire to the white wire (at "Heater Line 1 / 2 in the upper right of the board) didn't read any voltage when I first turned it on, but measuring with the black lead to ground gave me 123V on both. After several minutes, I heard a "BRRRRT" sound that lasted for about 2 seconds, then a flash behind the board near the upper right before the breaker flipped off. Then there was the not-unpleasant smell of pennies and ozone. I'm making an educated guess that this is when the board tried to turn on the heater, but shorted.

-

I've been working on this for about 2 months, so I'm hoping for a second opinion before I throw a ton of money at it. History This hot tub was here when I bought the house in 2004, so it's roughly 20 years old. It says "Blue Ridge Spa", which I've since learned is a division of Gatsby, which I think is a division of Jacuzzi. Over the years I've done all of the repairs myself, and have replaced pretty much everything except for hoses at one point or another. The problem In February 2022, I came home from a trip to find the hot tub completely drained and the power was off! It had gotten down to 18F while I was gone, so I assumed that something had frozen and burst. I didn't mess with it until July, when I traced it down to the pressure switch in the heater being blown out (literally, blown apart). I bought a used replacement heater and replaced the old heater and pressure switch, then filled the tub and turned on the breaker. Everything seemed fine, but after about 10 minutes the breaker flipped. I tried again while watching from underneath, and when the breaker flipped again I saw literal sparks behind the Heater 1 / 2 connection in the main circuit board. I unplugged the heater and flipped the breaker back on for testing. The incoming voltage is definitely 240V. I measured the voltage at the heater, and both legs have 123V. That's measuring with the positive lead on the hot wire and the negative lead on the green / ground wire. I haven't measured while the breaker flips, though. From there I replaced the heater yet again, just to rule out a bad second heater since it was used. After a few minutes, the third heater (with new pressure switch) flipped the breaker, too. That should eliminate the heater, pressure switch, and cords as the problem. Can you think of any other possible problem here OTHER than the circuit board?

-

Dreammaker Spa / Balboa not heating up

csdude55 replied to Quadder's topic in Portable Hot Tubs & Spas

Do you have a separate thermostat? I don't have the same hot tub, but mine has two different ones: a wet one in the filter well, and a dry one that's pressed against the heater. If that's not it, then I think you're running out of variables. I think that the only things left would be wires and the circuit board. -

I have a Blue Ridge Spa, which I think is the same as Gatsby but renamed. It was here when I bought my house almost 20 years ago, but I'm fairly handy and have replaced pretty much everything in it myself. Several months ago it developed a leak, but I didn't know it until recently. I discovered that the leak was coming from the heater, and when I took it apart I saw that the pressure switch was completely blown apart! So I put in a new pressure switch and reinstalled it. After I got it full, I turned it on and immediately had an "FL" warning... Flow Error. I took out the filters. Nope, still get the error. I tried toggling the jets a few times. Nope. But I had air coming out of the jets every time, so I'm pretty sure it's air lock. I burped the heater by loosening the lid until water came out. Nope. I went to the jet pump and opened both bleed lines until water came out. Nope. I loosened the intake on the jet pump until water came out, then the outtake. Nope. I used a plunger to try to force water in and air out. Nope. Finally, I drained it dry and then refilled it, making sure that the hose was in the filter cubby and aimed right in to the main intake. Nope. But again, when I turn the jets on for 10 seconds and turn them off, a few seconds after I turn them off I have bubbles and gurgling from 3 jet outlets. FWIW, the filters were in place for those months that it was empty, so there shouldn't be an issue of something big that's clogging the pipes. Plus, if there was a literal clog then I wouldn't have had so much water coming out at the heater and jet pump when I loosened them. I'm running out of ideas here. Any other suggestions?

-

Regarding Rockwool / Roxul, can you tell me the difference between these two? https://www.amazon.com/ROXUL-Mineral-Temperature-Insulation-Density/dp/B07JHWZGDW/ https://www.lowes.com/pd/ROCKWOOL-COMFORTBATT-R-30-Stone-Wool-Batt-Insulation-with-Sound-Barrier-15-25-in-W-x-47-in-L/3610406 All of the results at Lowes are ROCKWOOL COMFORTBATT, and talk about sound deadening. But it's R-30, versus the cheaper ROXUL from Amazon only being R-8. But I've read that R-ratings on this are irrelevant since they repel water, so I'm getting confused. Which would you recommend to go inside of a cabinet built with the insulation board that @RDspaguy recommended? Also, is the purpose of wrapping it in plastic to keep water out? With it being water-repelling I wouldn't think that step would be necessary.

-

I won't deny, $12 for a 4x8 sheet fits the budget a whole lot better! I could buy 4 sheets for $50 and make the cabinet 4" thick, having an R value of 17-20. For the sake of my electric bill, though, I'm kinda tempted to do both... bag up rockwool and pack it in, then build a cabinet around the outside for both protection and additional insulation. During the winter my electric bill hits $300 USD, so if I can knock $50 off of that then it would be worth the investment.

-

Under the deck is totally exposed. There was originally a thin wooden cabinet frame that was mostly cosmetic, but it had rotted away and I had to rip out what was remaining. So now the pumps, motors, and tubes are totally open air. The pumps and motors are a foot or two away from the shell, so I think it would be easy to tuck insulation in between the motors and tubes as long as it's pliable like the pink stuff. Unless you think I should tuck it between the tubes and the shell?

-

I'd never heard of Rock Wool, so I had to Google it. There are a LOT of things called Rock Wool! LOL Some are for planting sprouts, some for sound deadening, some that looks like the right thing for $20, and some that looks like the right thing for $600... it's hard to wade through it all. Is this what you're talking about? https://www.amazon.com/ROXUL-Mineral-Temperature-Insulation-Density/dp/B07JHWZGDW/ I was originally thinking about 2 of these, which is R-19 and 6" thick: https://www.amazon.com/Owens-Corning-E61-Fiberglass-Touch-Insulation/dp/B0044G35XU The Roxul in the first link would be 1/2 the price (very appealing!), but it's also 1/3rd the thickness so I'm going to guess that it's more equivalent to R-3 (I read that the R value doesn't really apply)? But Google does make it sound better for outdoor applications, and I hate to spend $200 on the pink stuff then have to replace it in a few years.

-

I have a Blue Ridge Spa by Jacuzzi, circa 2000 or 2001. It came with the house when I bought it about 15 years ago. It was originally on a cement slab to the side of the deck, and since then I rebuilt the deck to recess it. It originally had a 2x4 border (with 1" of it showing), and underneath that was a thin frame (maybe 1/4") to make it pretty. Inside of that frame was a piece of Styrofoam, maybe 1/2" thick. Over the years, though, that 2x4 had almost entirely rotted away, and half of the frame was rotted and falling apart. So for the last several weeks I've busted out the old border, ripped out the thin frame, and replaced the border with a 2x6... the photo below shows the new border, and I left 5" out so it could be used to sit wine glasses on. Underneath the deck, though, is where I have a question. The front of the hot tub (where you see the orange tag in right side of the photo) has been more or less exposed for the last 10 years, when I began replacing pumps and other hardware. The contractor put 2x6 rafters in front of the screws that held the frame in place so I had to break the frame off to get to the heat pump, and after that I just leaned it back in place. It never had Styrofoam or anything, so the only insulation was the foam that's adhered to the acrylic shell. The front is easy-access to the main circuit board, heat pump, and circulation pump. To the back-right is the jet pump. Back-middle, there's some sort of PVC junction that appears to be attached to the thin frame. That's the only part I couldn't get out, when I pulled on the frame all of this PVC started to come with it. On the left, there's nothing but tubes. I don't want to leave all of this exposed, so I was planning to staple a sheet of plastic to the bottom of the deck and let it drape down. Maybe lay 2x4s around the cement slab underneath, then staple the plastic to that, too... then it would be nice and stable, but easily moved when I need access. Question 1: is that OK to do, or would it cause condensation inside that might be a problem for the pumps and circuit board? Question 2: I'm in zone 7A, so sub-freezing temperatures aren't uncommon during the winter. Would you recommend any type of additional insulation around the shell? I thought about regular pink home insulation, tucked in between the pumps and the shell, but I wanted to run it by you guys and gals first.

-

I wanted to give you all an update, since you were all so helpful! For my project, I had to level my deck AND the hot tub; the deck had sunken down around the hot tub because the contractor didn't put any supports under it. I first emptied the hot tub, then had to chisel out the 2x4 trim that went under it. You can kind of see that trim in my pics before... it was originally stained brown, but it had mostly rotted away. Then I placed 2x6s under the edges so that it would raise when I raised the deck, and then I could see what to do underneath. Next step, I used a bumper jack at each corner to raise and level the deck. Now THAT was a pain!! I had my girlfriend stand on top of the deck with a level and yell when I was good, but one section under the deck only gave me about 18" of clearance! Not to mention the spiders and all the freakin' mosquitoes 😠 But I got it done. From here I could see the bottom right corner needed to be shimmed by about 1 1/2", the bottom left corner by about 1", and the top right corner by about 1/2". Not exactly what I had estimated before, so it's already good that I'm taking these extra steps! Next, I used pressure treated 2x4s to build a frame kind of snug around the bottom of the tub, sitting on top of the cement slab. I wanted to line it with plastic but I couldn't get the plastic to slide under the top left corner of the hot tub, and I might end up regretting that. Then I poured about 1/2 bag of leveling sand into the frame that I built, then took a 1/2" furring strip cut to 4' long to slide the sand under the hot tub. That took a little work to get past the tubes and everything! But once I got it in place I repeated adding sand several times to really pack it in, trying to make sure that the furring strip reached both sides of the hot tub at the same time. Once I thought it was really packed in well, I took another furring strip and placed it against the one I was using to slide, then tapped it with a hammer to really wedge it in there. Not TOO hard, I wanted to raise the tub off of those 2x6's by maybe 1/64"... just enough to release the pressure. Then I poured more sand, and repeated the process with a 1" strip. Then I poured more sand, and repeated with a pressure treated 2x4 (so really 1 1/2" thick). When that was done, everything had been shimmed and packed with leveling sand. Next, I used cinder blocks and wood to add support under the seats. These weren't originally supported before, but I figure... why not? Since I'm under here, dirty, sore, and covered in bug bites, I might as well make the most of it! LOL From there I filled the tub up, just a little at a time, and kept an eye out for any movement or sounds. I filled it about 1/8th, then let it sit overnight and repeated the next day. I didn't have any issues at all, so after it was filled and heated, we gave it a "test run" with two of us in there... no problems at all! Last step, I cut new trim out of those 2x6s, stained it, slid it under the edge of the tub, and used structural screws from underneath to mount them in place. I have 1" of wood under the edge of the tub, and 5" showing; I specifically wanted it to be wide enough to sit wine glasses or whatever. I have some pics of the trim below... I took some underneath to show the finished shimming, but you really can't make anything out so I didn't post them. Either way, I hope this helps others with the same problem in the future!

-

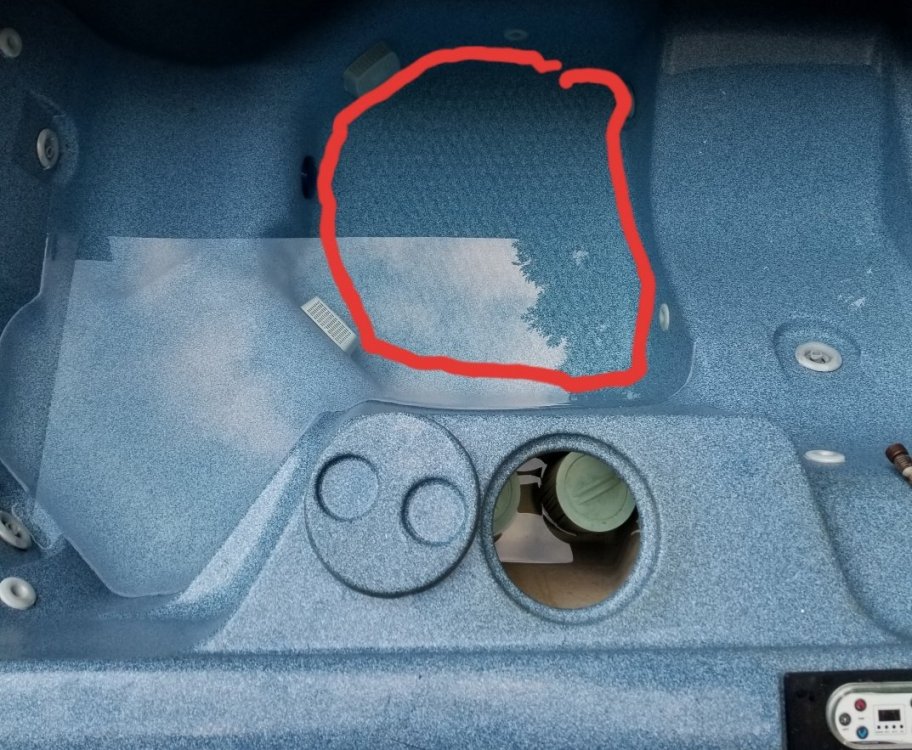

You're right, replacing it really isn't an option. $1400 for a new slab of concrete, plus at least $2700 for a new one (the cheapest I've found that would fit)? For something that I might use 5-10 times a year? I just don't see it happening. When/if the shell cracks, I'll probably just pull it out, replace the deck boards where the hole is, and be done with it. I like your idea of giving it a gravel bed... maybe paver base? I'll still have to pull the whole tub out, though, which is much easier said than done! To get it to lift 2" took my full body weight... with the water logged / rotted skirting and plywood bottom, it has to be 500lbs. Maybe I could get 4 car jacks under there to lift it up a foot, then build the frame under it? I'll have to think on that one. I'm attaching a couple of pics for you. The part that I circled in red is the only part touching the cement slab. It measures 30" left to right, a little more than that front to back; you can see it's odd shaped, so it's hard to be exact. But a 48" x 48" frame would be more than enough to fit under it.

-

Quote to have a local spa company lift it, jackhammer out the old concrete, then pour gravel, rebar, and a new cement slab... $1400. And the guy is an old high school friend, so that's probably a great price on it :'-( I'm tempted to shim underneath with a 1x4 and then a 2x4, then shoot spray foam under it as thick as I can for additional support. In theory, it would hold the weight easily: http://blog.achfoam.com/?p=1592

-

Unfortunately, @Cusser, I think Blue Ridge Spas went out of business sometime around 2000 😞 There are a small handful of companies that sell parts to fit it, but they're actually Gatsby instead of Blue Ridge Spa so even the OEM parts aren't available. @ratchett, I thought the same thing when I first began replacing parts! Should I spend $200 on a part to keep an old hot tub alive? But at the time it was cheaper and easier than replacing... I probably have $1,000 invested in parts by now, but now there's literally nothing left that's original other than the PVC pipes and the shell. The PVC is cheap to replace, too, so unless the shell itself breaks then it SHOULD last another 15+ years! I'm pretty sure that the old homeowners put it in themselves, and the cement slab is probably nowhere near as thick as it should be. I base that on the fact that they built a garage with a cement floor, too, that has cracked and leaks when it rains. So the right way to fix it would be to pull out the tub, repour the cement slab, and then put it back in... but with the deck built around it now, that's not as easy as it sounds! It'll probably mean tearing out a part of the deck and rebuilding it. Should I invest another $2,000+ to reset a 17+ year old hot tub? (Moot question, really, cause I don't have $2,000 to blow on it! LOL) But with it being so unlevel it's not usable, either. I have water to the rim on the front (where the control panel is), and the jet in the back left shoots water in the air! Grrrrr 😠

-

I bought my house 17 years ago, and it had a Blue Ridge Spa by Jacuzzi already installed on a cement slab. It's roughly 80" x 80" and holds 4 people. If you're not familiar with it, I know that I've been able to use Gatsby parts as replacements. Since then I had a deck built around it, and have personally replaced every piece of hardware on it; the only thing that hasn't been changed is the shell and pipes, seriously. But over the years, that cement slab seems to have sunk on one side, so the tub is no longer even close to level. While sitting in it comfortably, one of the jets is so close to the surface that it shoots water out of the tub! I emptied it today and used scrap wood around the top to shim it up and get it level: two corners had to be lifted by 2", and the third corner by 1". But here's my question. I have no idea where the shim points on this tub would be, and from underneath I'm not even sure how it's sitting! There's nothing beneath the sitting areas, so there appears to be 18" or so of totally unsupported shell in each corner. The best I can tell, there's maybe 40" x 40" of the bottom of the shell that's actually sitting on the cement, but I can barely reach it from the front because I have to worm around the circuit board, pumps, and motors. There's a plywood bottom underneath the motors, but it's way beyond rotted away. And most of the skirting is, too, so I can literally pull it apart with my fingers. With it empty and lifted from the top, can I just shim the 3 corners of that 40" area (between the rotted plywood and shell) with cement pavers and plastic shims? Or is that really allowing too much pressure in the middle of that 40" area and in the sitting areas?