-

Posts

19 -

Joined

-

Last visited

Everything posted by ScenicCabinRentalsRRG

-

An update, This goop is some sort of potting compound because the back side of another topside I handled recently also had this goo filled around the PC card on the back side of the topside. Does anyone know what type of potting compound this is? It is transparent and sticky and slimy to the touch. I don't believe it is an uncured or bad batch because it is very consistent between units that I am working with. Thanks as always. Dan

-

Hey Guys, I had to replace a topside overlay on a relatively new Viking Spa HER61 with a TP600 topside and found a bunch of slippery crud jammed in the depression between the panel and buttons after removing the old overlay. I was scraping the residual adhesive off and cleaning the plastic and noticed the gap around the buttons was filled with goop. When I disturbed it with my ISO-alcohol soaked rag, it seemed to make the surface very slick and not clean enough to apply the new overlay. It ended up being a long battle versus a 15 minute overlay replacement to get the plastic down to where I felt like I had clean material for the overlay to adhere to. It initially thought: mold release but it could not have been. What is that stuff and what should I do to prep the topside surface for new overlays next time? As always, Thanks in advance for any help you can assist me with. Dan

-

There's a few things it could be: 1. debris clogging the passageway between the Jet Body and face. Solution, remove the jet and clear out the debris. 2. the Jet has been rotated past its normal stops and the valve is incorrectly oriented. Solution, same as previous possibility. 3. The supply flexible tube to the jet is kinking under its own weight at the manifold, or coming off the jet. solution, pull the panels behind the jet and find the kink. Then support with zip ties so it relieves the kink. It will not go away right away, but you should notice an improvement almost right away. Also try closing some of the other jets and see if the flow improves. It might blow out debris if you do this which might also help. Cautionary note: if it is an old tub, do not pull, move and disturb anything more than you need to. Attachment stems love to snap themselves off which would leave you with a real mess on your hands. Happy Tubbing!

-

Hey all, Is there any Wi-Fi control modules that are compatible with non "BP'' Control packs? I hae a VS501 control pack in the tub I am trying to get connected to Wi-Fi. I would have imagined that there would be a way to tap into power on the 115VAC bus and Tee off the main topside control and run the inputs from the WiFi pack right into the topside connector. The controller does not care where the inputs come from, it just responds to the commands. But I am not an enginerd so I could be totally out of line here. Thanks in advance as always for any help that can be provided. Dan

-

Help with Hot Tub Cover Purchase

ScenicCabinRentalsRRG replied to damianinpa's topic in Portable Hot Tubs & Spas

I concur with Dave about longevity. I replaced 5 hot tub covers 3 years ago and got the cheapest bottom line cover you can get and I have already replaced 3 of them for water logging, kids walking on and breaking the foam etc. Ski resorts are about the only places who can justify cheaping out on the covers because they can afford to buy in bulk and discovered that even the top end model covers didn't stand a chance against patrons unfamiliar with spa care and can switch them out as needed. A proper cover will cost around $550. But it will last a lot longer. We have been re[lacing tubs with Strong Spas with the hard covers specifically because of this recurring cost. -

Hey all, I am wiring up a Circ Pump that is 240VAC but only has a 3-wire cord (white-black-green) and is my 1st time encountering a 240VAC component that does not have a 4 wire cord. Do I need to label the plug that it is 240 Volt, or label the white wire as a hot so I do not confuse the next guy behind me? Is is more common practice among techs to just use a 4-wire cord and leave the white leg coiled at the termination point in the pump? I know how the pin outs need to be in the amp plug, and have set the control board for a 240V circ pump. My question is specifically on what common practice is for identifying to the next guy behind me that this is not a 115VAC powered component beyond the marking on the motor itself. Bonus Question: What tool do I need to De-pin the amp plugs? They are TE Connectivity Mate-N-Lok connectors and calls for extraction tool P/N: 318851-1 and is $55 dollars shipped. I know there has to be a less pricey extractor for this connector as they are everywhere. As always, any help is much appreciated Thanks. Dan

-

Hey Dave, Thanks so much for the reply. Very informative and confirms many of my thoughts. My main reasons from shying away from Gecko is because of the availability of PC cards, Heating elements, Heater assemblies and overlays. The Gecko system just does not seem service friendly which is critical for my line of work. Hot Tubs are a necessary amenity in the line of work I do. Not too many people want to rent a vacation house that does not have a hot tub as I have discovered. I do not mind spending money on hot tubs, but prefer to do due diligence and go with a brand who does allow repair and maintenance without spending huge sums of money on higher assemblies. Secondly, the Balboa system seems much more stable and less finicky than the Gecko systems. Balboa's temperature sensing system seems really stout. The temp probes are the same part for both ends of the heating system and when a failure occurs the fault code often brings you to the part that needs to be replaced, and then you can buy that part. You mentioned another point that I favor Balboa over Gecko, the initial setup. Gecko has good manuals, but the Balboa dip switches make it impossible for guests to find their way into the programming sequence from the topside. The tub that brought me here is being converted to a Balboa system so the Gecko system is going away in this case. Thanks for the pointer on the detailed fault code, I will check that out for sure. My thought about the high energy use is how the filtration cycle, sensing systems, control programming, and parasitic drain between the systems might be different. To me, it seems the Balboa's use less energy overall when all other factors are equal. As for the heating elements, I have been advised to change elements with 5.5kw at every opportunity because yes the 4.0 heaters use less energy, but the longer time the heater has to run is also a longer time that the pump has to run as well. Thanks for the thoughtful and informative reply as always. Dan

-

Hey Guys, I was wanting to get some other spa maintenance Tech input and or corrections if I am wrong about anything I have experienced below: I think I have had my last straw with Gecko and not being able to service anything besides replacing major sub assemblies of control systems. We have 50+ hot tubs in our program most of which are Balboa or Gecko. All of the topsides of our Gecko systems look trashed because as far as I am aware, you cannot buy an overlay like you can with a Balboa unit. Our Balboa controlled tubs look great because we are able to replace the overlays. We just had a large tub go down running a Gecko in.xe type system with a "HR" fault code. According to my counterpart in the area, he has replaced this pack 2 times before this most recent fault. He advised me that this is an unrecoverable message, that the pack must be replaced and costs close to $1000 to do so. I decided that because of this trend I have noticed with Gecko that I am not going to return to service any Gecko system that has a failure anymore. I am in the process of pulling out the Gecko System and upgrading it to a Balboa system. It is a 2 pump with blower system,o-zone, led lighting system, and audio system so it will be a big job, but the whole conversion still costs less than the lone control box. I still would have the lousy looking topside with all of the text missing from the control buttons. And no one sees the control boxes. The Gecko in.xe system that is being replaced is a very nice looking unit. color coded plugs, molded connectors on the leads to the pumps. O-ring seals around the case covers. It is very professional looking and 'instagrammable' at glance, but this inability to service anything in the control or purchase overlays is a deal breaker in my eye. I also believe they have a higher power consumption than a comparable Balboa unit. For instance our single pump 5.5kw heater tubs average 12-14ish amps while circulating and warming water. The Gecko tub we have is a steady 19 amps when running. The home owner is not happy with his electrical bill and I am tempted to recommend retrofitting the pack with a balboa system. Has anyone else made this observation as well? Thoughts? (I promise I have no vested interest to Balboa or any Manufacturer. My background is airplanes before this so I have no history with anyone. My allegiance lies with whoever has enough faith in us techs to build systems to be maintainable. This throw away culture is hurting us.

-

Hey Dan, Thank you for the reply. I checked the info on the stuff you use and looks great for the heaters. Can you recall if the people you mentioned using the Deacon brand stuff used the 770 (200-950F) or 7228 (-25 - 450F) I imagine it would probably be 7228 as the paste needs to be able to perform before the spa is put into use or in storage where it could be exposed to colder temps. Thanks again, I think the 7228 thread paste looks like the best material for the job as long as it does not react with the o-ring material which mine are Viton. I can't remember if that is what is used at the Balboa factory. Thanks again! Dan

-

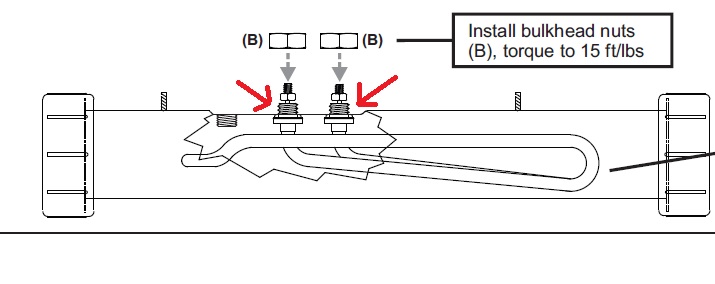

Hi All, I replaced a heating element in a Balboa control system and noticed when I removed the nuts that attach the element to the pipe that there was some sort of sealing compound in the threads. I searched for a while what type of thread compound this might be but am finding out there are many types of thread compound out there. I am not familiar with pipe dope, thread sealant, thread compounds etc and figured someone on here might be able to point me in the right direction. The best conclusion I can come to is that it is the same kind of pipe thread that might be used on a water heater element with straight threads, not NPT, and are rated for hot water environments. Looking at several different heating element replacement instructions there is no mention of using pipe thread sealant but I am positive one is used at the factory and then painting polyurethane to seal everything after the electrical connections are made. I want to do these replacements by the book and use this material for cleaning up dirty connections on further repairs. Thanks as always, for any help you may be able to provide. Dan

-

Something that comes to mind is there may be a bad seal up high in the tub somewhere above the fill line that when enough water is displaced (in your case 3 people), or the tub is overfilled, water might start leaking through this bad seal onto electronic components and short them out causing your GFCI to trip. I'd also try running everything in your tub so it is drawing max current IE lights, jets, blowers, heater, the works, and let it run for a few minutes just to be sure the power supply is adequate. It's an easy check to do. That way at least you can eliminate the possibility. Hope this can begin to help. Dan

- 2 replies

-

- circuitbreakers

- vanguard

-

(and 3 more)

Tagged with:

-

Forgive me, I think I may have been unclear about the benefit I have noticed. I have not noticed any difference between the performance of standard vs. microban filters in service as far as filtering and improving water quality. I can say though, the microban filters take a fraction of the time to rinse out dirt when cleaning the filters with a hose. The white filters tend to hold onto the dirt more. Or was that what you were saying? I found your comments very helpful and interesting. I will keep an eye out for those features you mentioned. Dan

-

I do not work for Premium Leisure or any spa manufacturer or component manufacturer. I will reciprocate your question by asking if you were denied a job with, or terminated from Premium Leisure that might sway your opinion of them besides the explanation you provided? Full foam tubs are nice for the user because it keeps the energy bill a little bit lower, but they are more expensive to work on because everything is petrified in foam. True, however anti-microbial filters (the ones with blue ribs, sometimes red I think) make cleaning a breeze versus the standard white pleated filters. Also, you are doubling your cost of replacing filters when the time comes to do so. All things to keep in mind. Happy Hunting Dan

-

I can only speak for Premium Leisure as a brand that they are one of the better companies when it comes to customer support. They keep track of their tubs and what equipment each one is outfitted with which does not sound like much, but it is amazing how many tub builders don't know what they are building or with what components they are putting in them. In that way I think you have made a wise choice going with them. As far as your model tub, it looks like a nice setup, it runs on 240 volts which is good, do not consider 120v if you are shopping for hot tubs. It looks like it uses Balboa and Waterway components. Both are market leaders of components. The tub itself is the glossy type which tends to help make water maintenance a little easier and keep clean longer but does require occasional treatments to the surface to keep that wet slick look and feel. For elderly people, the slick surface does not provide the best traction so if there are elderly users, you may consider a hand railing or some sort of grip mat for additional traction. The example pictured on the website has 5 suction inlets so this tub moves some serious water! Hope this beings to help you. Happy hunting and good luck! Dan

-

Hey Dave, We Just added a Cabin to our program in which the owner opted to buy a saltwater tub and initially it sounded great, but after research, I decided we were not going to retrofit any more tubs to this configuration and that was one of the reasons. As far as the copper bands still coming from Balboa, they used that system for a long time so it will be around for a while as thousands of tubs new and old still have the old system and guys like us will still need part support, but the new system is out and seems like it should be a great solution to the problem. Now back to the heater assemblies, can you or anyone advise as to what type of thread paste is being used on the bulkhead nuts? It is a white looking paste that is kind of flaky when removed. It looks like they use this thread paste I assume, but do not know what type, and then if the heater tube is being installed in a control box, they coat it in polyurethane or maybe conformal coating after attaching the copper bands. This is guess based on what I see, so if anyone can say for sure please let me know as I want to repair these using the exact same process they use. Thanks for the help thus far. Long term I am looking to build a testing fixture to do anything from run control boards, heaters, pressure leak checks of the heaters and pumps, etc. Will start a thread if anything useful comes of it that I feel might be worth sharing. Dan

-

Hey All, I just got a few sets of Viton O-Rings from Mcmaster-Carr (https://www.mcmaster.com/#1288N143) linked here and I do have to say the diameter is just a touch small and the cross section a touch thicker than the ones removed, but I threw them back together anyway, torqued them and seem to be holding a seal just fine. I checked to see if they squeezed out or pinched and they look just fine. One last question relating to this topic, does anyone know what kind of thread paste is being used on the threads? I took apart a brand new heater and saw that the threads and oring seat were coated with a layer of white paste looking material. Jersey Hot Tub Repair: Thank you for the input. The elements I am replacing the O-rings on are because of the corrosion. I thought if I could catch the corrosion early, I could save the elements and control boards from undue stress and premature failure. I did a resistance check and the measurements are within range so I assumed that was a measurement of the 'health' of the element. I have seen the evolution in process Balboa has progressively been adapting to improve the corrosion and leaking in this area up until they did away from the copper tongue depressor shaped attachment bands and went to a plug type connection. I cannot figure out why they did not do from the beginning. I clean the corrosion from the terminals, replace the rings and ultimately the thread paste, re-attach, center, torque and applying a generous portion of dielectric grease over the bare copper and where the corrosion was. Balboa appears to be applying a sort of polyurethane or conformal coating over these exposed connections which seems to have pretty much solved the corrosion problem. The tub in question is one of the few wholly owned cabins we have in our program. Thanks everyone for the help. Dan

-

danthespaman316 - Thank you very much for the dimensions. Using the ID, and OD sizing guide I can find a few Viton O-rings that are very close matches and one perfect match. Do you or anyone happen to know if the size #10 mean that it is a 3/32'' thickness? The reason I ask is because when I do a search by "#10" I get results for Hillman and Danco o-rings, and those are 'rubber' and neoprene o-rings. 3/32'' is the size of the match that has the same ID and OD that you kindly provided. Thanks again for all of the help. Dan

-

Hi Everybody! This is my first post on the forum and am excited to have discussions with pool and spa professionals from across the country! I hope that I can share my knowledge though limited at this point, and hopefully help a few fellow spa owners. I manage a maintenance department for a cabin business that is my user name and we services about 50+ hot tubs of many brands including Nordic, Strong Spa, Premium Leisure, Coleman, Viking, Gulf Coast among others. I look forward to adding this forum as an information tool in keeping our equipment top notch. Now on to my question. I have been searching for the O-rings that are used on the Balboa Thru-pipe style heating elements that seal the electrical terminals as the pass through the tube. They call them ''bulkhead O-rings'' but there is no part number to order just these o-rings when they wear out. Does anyone out there have a good replacement O-ring for this as I have been unsuccessful in my search. Additionally, does anyone have the measurements for the o-rings when they are new? I want to order a bunch of Viton O-rings but could use the specs to ensure I get the right ones. Thanks in advance for any help you can provide. Dan